Stoelzle Glass Group

About Glass

GLASS HAS AN INHERENT BEAUTY, TACTILITY AND VERSATILITY. AS A PACKAGING MATERIAL IT IS UNDOUBTEDLY IN A LEAGUE OF ITS OWN. IT IS INFINITELY RECYCLABLE, WITHOUT SUCCUMBING TO A LOSS IN QUALITY.

It satisfies the global interest of sustainability, consists of 100% naturally occuring ingredients and can be reused and refilled without posing a risk to health and safety.

THE GLASS MADE BY STOELZLE IS SODA-LIME-SILICA AND IS SIMILAR IN COMPOSITION TO MOST CONTAINER AND WINDOW GLASS MANUFACTURED AROUND THE WORLD.

Clear glass, known as extra white flint, makes up 70% of Stoelzle production. The remaining 30% is our production of brown (amber) and green glass. We also produce 30 specialist colours on 4 separate lines.

GLASS IS COMPOSED OF BASIC RAW MATERIALS: SAND, LIMESTONE, SODA ASH AND CULLET (RECYCLED GLASS). THESE, PLUS SEVERAL OTHER INGREDIENTS ARE WEIGHED AND MIXED IN A BATCHING PLANT AND THEN DELIVERED TO THE FURNACE FOR MELTING.

Melting requires temperatures of up to 1600°C. A combination of gas firing and electricity is used but a large part of the process is simply time. It takes up to 2 days to for the materials to melt appropriately before bottles can be made.

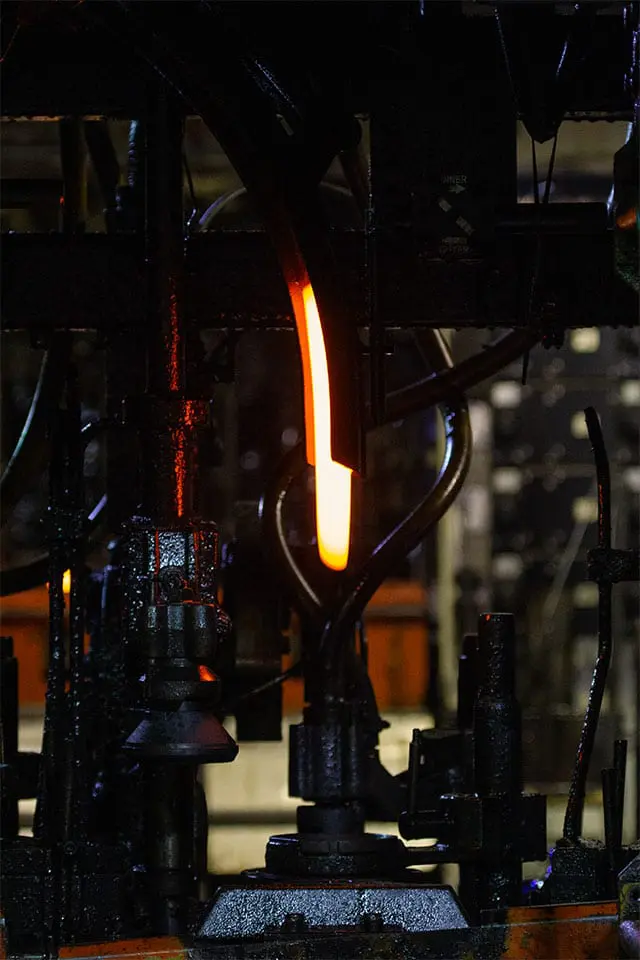

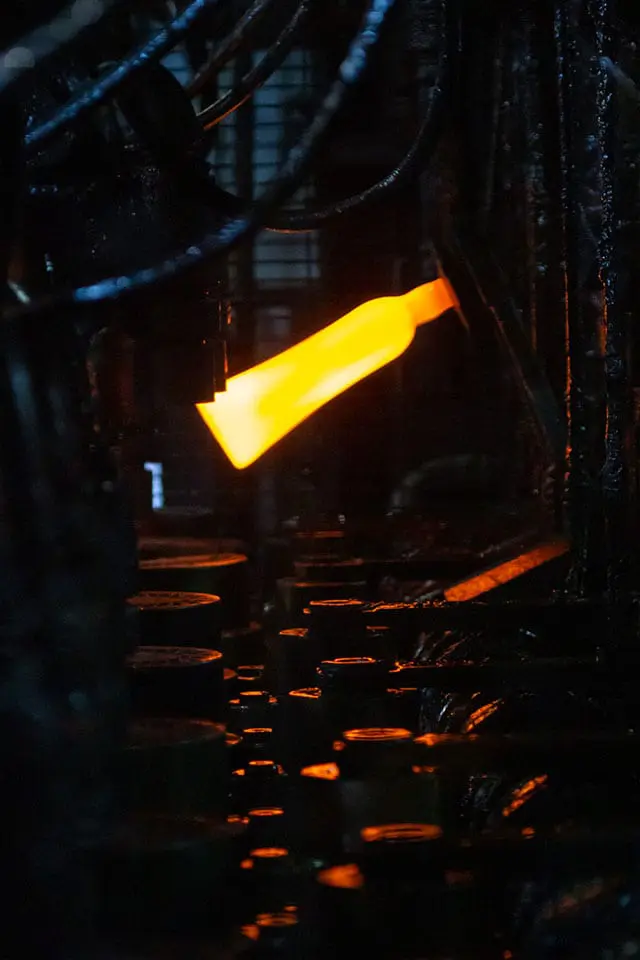

BOTTLE-MAKING IS A HIGHLY AUTOMATED ENGINEERING PROCESS WHICH INVOLVES THE COOLING AND FORMING OF HOT GLASS GOBS INTO BOTTLES.

Cast iron moulds and compressed air alongside electrical driven equipment comprise an IS machine. This performs the impressive conversion of a viscous liquid into a solid object in a matter of seconds.

FOLLOWING THE PRODUCTION PROCESS, BOTTLES REQUIRE ANNEALING OR STRESS RELIEVING DOWN A HEATED TUNNEL CALLED A LEHR WHERE THEY ARE RE-HEATED AND THEN SLOWLY COOLED TO MEET ROOM TEMPERATURE.

At the end of the lehr the outer surface of the bottles receive a coating as a protective layer. This ensures the bottle can withstand handling requirements down the inspection lines, at the customers’ filling line and so on.

A COLLECTION OF AUTOMATIC FAULT-FINDING MACHINES ARE ON THE GO IN THE INSPECTION AREA, CHECKING ALL BOTTLES FOR GLASS OR MANUFACTURING DEFECTS.

These machines are equipped with various optical techniques to perform this duty. Built-in communication features enable fast response by both inspection and production staff who are on hand to perform corrective actions.

Stoelzle Services

ELEVATING YOUR BRAND IN A COMPETITIVE MARKET

Service

Standard

Collection

With three unique tiers, the Eco, Status, and Heritage lines, these one-of-a-kind designs will ensure your product stands out.

View Standard Collection

Service

Premium

Bespoke

Have an idea for a bottle that’s different to the rest? With our design expertise, state of the art technology and high quality glass, we can turn your ideas into reality.

View Premium Bespoke

Service

Decoration

We have a range of innovative decoration techniques to offer, giving your product extraordinary visual and tactile qualities.

View Decoration

Service

Caps & Closures

We offer bottle design and closure services as part of a wholistic approach.

View Caps & Closures

Service

Design

Our in-house design team, based in the UK, combines innovation and artistry to create unique, high-quality glass bottle packaging solutions.

View Design

Let's Connect